Are you worried about what touches your baby's sensitive skin? Choosing the right wipes can feel overwhelming with concerns about harsh chemicals or materials. Understanding how baby wipes are made gives you confidence in their safety and quality.

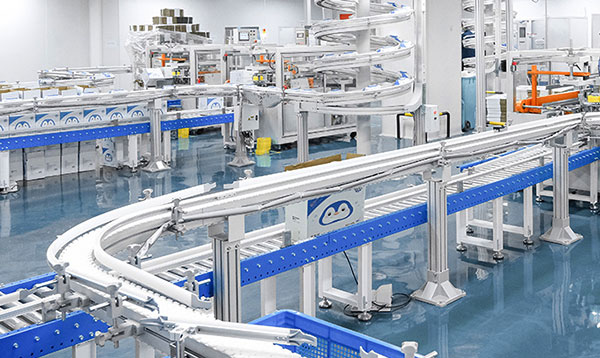

The production of baby wipes involves several key stages. It starts with preparing the non-woven fabric, mixing the wetting solution, saturating the fabric, cutting and folding the wipes, and finally, sealing them in moisture-locking packaging in a controlled, hygienic environment.

This entire process happens under strict quality controls. We need to ensure every wipe is safe, gentle, and effective. It begins with choosing the right base material, like soft cotton or sustainable bamboo. Then, we create a mild liquid solution, usually purified water mixed with gentle cleansers and skin conditioners. The fabric is then soaked in this solution. After that, machines cut and fold the wipes precisely. Finally, we package them carefully to keep them fresh and prevent contamination until you open the pack. It’s a detailed operation from start to finish.

Making the fabric ready is the first big step. We often use non-woven fabrics because they are soft but strong. Think materials like plant-based fibers, bamboo, or organic cotton. We make sure these are clean and properly processed into large sheets. At the same time, we prepare the liquid solution. This usually has a lot of purified water, maybe over 9 S0%. We add things like mild soaps, moisturizers such as aloe vera or chamomile extract, and safe preservatives to stop bacteria growth. The goal is a gentle, effective liquid.

How are the raw materials selected and prepared?

The foundation of a great baby wipe is the material itself. Choosing the right one is critical for performance and gentleness.

Raw materials like organic cotton, bamboo, or plant-based fibers (PLA) are selected based on softness, strength, absorbency, and eco-friendliness. These fibers are then cleaned, carded, and bonded using methods like hydroentanglement (spunlace) to create soft, durable non-woven fabric sheets.

Material Matters

Selecting the right substrate isn't just about feel; it impacts performance and sustainability.

Comparing Common Wipe Substrates

Different materials offer different benefits. Here's a quick comparison:

| Feature | Organic Cotton | Bamboo Viscose | PLA (Plant-Based) |

|---|---|---|---|

| Softness | Very High | High | Moderate to High |

| Strength | Good | Very Good | Good |

| Absorbency | High | High | Good |

| Sustainability | Biodegradable, Renewable | Biodegradable, Fast-growing | Compostable, Renewable |

| Key Benefit | Hypoallergenic, Natural Feel | Silky Texture, Stronger | Eco-friendly disposal |

| Consideration | Can be more expensive | Processing can vary | Compostability needs specific conditions |

At BBWIPES®, we work with clients like Luca Moretti, who values premium, natural ingredients, guiding them to options like organic cotton. For others focused on strength and eco-credentials, like Henrik Sørensen, bamboo or PLA might be better fits.

Ensuring Material Purity and Quality

Before any fiber becomes a wipe, it undergoes strict checks.

- Source Verification: We ensure materials come from certified suppliers, like those providing FSC-certified pulp for packaging or organic certifications for cotton.

- Raw Material Screening: We test incoming fibers for contaminants and microbial presence, following standards like ISO 11737-1. This ensures purity from the very start.

- Physical Property Testing: Initial checks on tensile strength and basis weight confirm the material meets the specifications for the intended wipe type.

This initial quality gatekeeping is fundamental to producing a safe and reliable final product.

What goes into the wetting solution for baby wipes?

Parents often ask about the liquid in baby wipes. It's crucial that the solution is gentle and safe for delicate skin.

The wetting solution primarily consists of highly purified water (often over 99%). It also contains mild cleansing agents, skin conditioners like aloe or chamomile, pH balancers to match baby skin, and safe, minimal preservatives to prevent microbial growth.

Anatomy of the Wipe Solution

The liquid component, or 'lotion', is carefully formulated for safety and effectiveness.

Common Ingredients and Their Roles

Each ingredient serves a purpose:

| Ingredient Type | Function | Common Examples | Why It's Important |

|---|---|---|---|

| Water (Purified) | The primary base and solvent | USP Grade Purified Water | Ensures purity, prevents mineral irritation |

| Cleansers (Mild) | Gently lift away impurities | Coco-glucoside, Sodium Lauroyl Sarcosinate | Effective cleaning without stripping natural oils |

| Humectants | Attract and retain moisture on the skin | Glycerin, Propylene Glycol | Keep skin hydrated |

| Emollients | Soften and soothe the skin | Aloe Barbadensis Leaf Juice, Chamomile | Provide comfort, reduce potential irritation |

| pH Balancers | Match the solution's pH to baby skin (≈5.5) | Citric Acid, Sodium Citrate | Maintain skin's natural protective barrier |

| Preservatives | Prevent bacteria, mold, yeast growth | Sodium Benzoate, Phenoxyethanol | Ensure product safety and shelf life |

We formulate solutions to be alcohol-free and hypoallergenic. For clients like Priya Kapoor exploring wellness trends, we can even incorporate specialized ingredients like CBD using nanoemulsion technology for better absorption, adhering strictly to regulatory requirements.

Testing for Safety and Compatibility

Safety is paramount.

- Dermatological Testing: We ensure formulations are tested on human skin under dermatological control to minimize irritation risk.

- Preservative Efficacy Testing (PET): This confirms the preservative system is effective against microbial contamination over the product's shelf life.

- Compliance: Formulations meet strict standards like EU Cosmetics Regulation 1223/2009 and FDA guidelines. We ensure they are BPA-free and use ingredients compliant with REACH.

- Custom Formulation Testing: For unique formulas, like the olive oil-based wipes for Luca Moretti's brand, we conduct stability and compatibility tests to prevent issues like ingredient separation.

How are baby wipes cut, folded, and packaged?

Once the fabric is saturated with the solution, it needs to be prepared for easy use and kept fresh. This involves precise cutting, folding, and packaging.

Large rolls of saturated non-woven fabric feed into machines that cut them into uniform individual wipe sizes. These wipes are then automatically folded (often interfolded for pop-up dispensing) and stacked before being sealed into airtight packaging like flow-packs or tubs.

From Roll to Ready-to-Use Pack

This automated stage focuses on consistency, convenience, and preservation.

Why Folding Patterns Matter

The way wipes are folded affects how they dispense:

- Interfolded (Pop-Up): Each wipe pulls the next one up slightly. This is common in soft packs and tubs for easy one-handed dispensing. Very convenient for parents.

- Z-Fold / C-Fold: Wipes are folded individually and stacked flat. They don't pull the next one up. Often used in smaller travel packs or specific applications.

The choice depends on the desired user experience and packaging type. Machine calibration is key here to ensure consistent folding and stacking.

Modern Packaging Features

Packaging does more than just hold the wipes; it protects them.

- Moisture-Lock Seals: Crucial to prevent wipes from drying out. This includes rigid flip-top lids on tubs or resealable adhesive labels on flow-packs.

- Material: Packaging materials are chosen to be impermeable to moisture and air. We use quality films and rigid plastics.

- Innovations: We offer features like flip-top dispensers with integrated UV lights for extra sanitation, or compostable sachets designed to meet eco-friendly goals (like those needed by Henrik Sørensen), guaranteed to degrade within a specific timeframe.

- Customization: Packaging is also a branding opportunity. We created bespoke Art Deco packaging for a French luxury hotel chain, integrating their brand identity directly onto the product.

Checking the Seal and Count

Quality checks continue right up to the final seal.

- Seal Integrity Testing: We use methods like vacuum chamber testing to simulate pressure changes (like air travel) and ensure the seals won't leak or allow air in.

- Weight Checks: Automated checks ensure the correct number of wipes and amount of solution are in each pack.

- Visual Inspection: Final packs are inspected for defects in printing, sealing, or overall appearance.

What quality control measures are essential during production?

Maintaining high quality throughout the entire production process isn't optional; it's essential for baby wipes. Safety and consistency are our top priorities.

Essential quality control includes: inspecting raw materials, continuously monitoring the production line (solution pH, moisture levels, machine settings), testing wipe physical properties (strength, dimensions), checking for microbes, and verifying final packaging integrity.

Ensuring Excellence at Every Step

A robust Quality Management System (QMS) touches every part of production.

Our Multi-Stage Inspection Protocol

At BBWIPES®, we use a rigorous 4-Stage Inspection Protocol:

- Raw Material Microbial Screening: Before use, materials are tested based on ISO 11737-1 to ensure they are free from harmful microbes. This helps avoid contamination from the start.

- In-Line Process Monitoring: During production, we constantly check key parameters. This includes 5-point checks per batch for the solution's pH and the wipes' absorbency/moisture levels. Machines are calibrated regularly.

- Tensile Strength Validation: We test the wipes' strength using methods like ASTM D5034 to ensure they won't easily tear during use.

- Final Packaging Seal Integrity Testing: As mentioned, we use vacuum tests and other methods to confirm the packaging is perfectly sealed to maintain shelf life and prevent leaks or drying.

Meeting Global Standards and Certifications

Compliance isn't just paperwork; it's proof of quality and safety.

- Facility Certifications: Our Wenzhou facility is ISO 9001 (Quality Management), GMP (Good Manufacturing Practices), and ISO 22716 (Cosmetic GMP) certified.

- Product Compliance: We ensure wipes meet regional standards like FDA 21 CFR for the US market and EU Cosmetics Regulations. We can produce EN 14476-certified virucidal wipes needed by healthcare clients like Emily Thompson's group.

- Ethical and Eco-Certifications: We hold certifications like Cruelty-Free International Leaping Bunny, use FSC-certified packaging materials, and comply with Sedex SMETA ethical audits.

Tracking Every Batch

Traceability is vital, especially for sensitive products like baby wipes.

- Lot Coding: Every pack of wipes gets a unique batch code. This allows us to track its entire production history, from raw materials to shipping.

- Documentation: We maintain detailed records (Batch Manufacturing Records) for each lot. This is crucial for quality investigations and essential for clients like Emily who need GHS-compliant Safety Data Sheets (SDS) and reliable documentation.

- Recall Readiness: Though rare, robust traceability allows for swift and targeted action if a problem is ever detected, backed by our $2M product liability insurance.

Why Choose BBWIPES® for Your Baby Wipe Needs?

Choosing a manufacturer for baby wipes is a big decision. You need a partner you can trust for quality, safety, and reliability. With over 12 years of experience, BBWIPES® is dedicated to exceeding expectations.

We offer:

- End-to-End Expertise: From selecting sustainable materials like organic cotton or bamboo to developing custom, hypoallergenic solutions, we manage the entire process in-house. Our vertical integration means faster turnaround and better control.

- Proven Quality: Our ISO, GMP, and ISO 22716 certified facility operates under strict 4-stage quality controls. We meet demanding global standards like FDA, EU regulations, and offer specialized certifications like EN 14476.

- Customization & Innovation: Need a specific formula, like CBD-infused wipes or argan oil facial wipes? Our R&D lab develops bespoke solutions. We pioneered AquaRise® tech using 30% less liquid with full efficacy.

- Reliable Partnership: We understand diverse market needs, from US healthcare (like helping a client achieve FDA 510(k) clearance) to European luxury brands and Middle Eastern travel retail. We offer flexible MOQs (from 10k units) and agile global logistics.

- Eco-Conscious Focus: We champion sustainable options like PLA non-wovens, compostable packaging, and provide carbon footprint reporting.

Ready to create premium baby wipes tailored to your brand?

Contact Timothy Wei | Global Business Director

Timothy@bbwipes.com | +86 13750830177

www.bbwipes.com (Live chat support available)

Conclusion

Making baby wipes involves careful steps: choosing soft materials, mixing gentle solutions, cutting precisely, and packaging securely. Strict quality checks ensure every wipe is safe, effective, and ready for sensitive skin. Choosing an experienced manufacturer matters greatly.