Need quality wet wipes consistently? The production process seems complex. But understanding it helps you choose the right partner for your brand's needs.

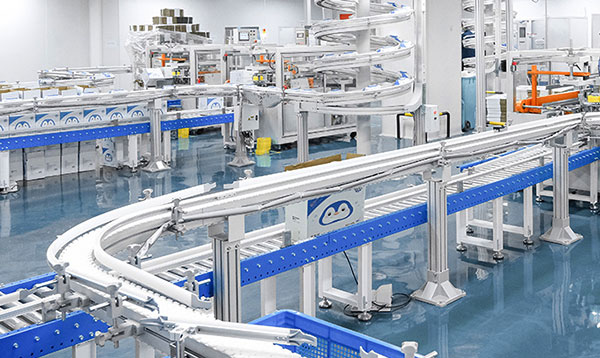

The production process involves several key steps. First, we select and prepare the non-woven fabric1. Then, we add the liquid solution. After that, machines cut, fold, and package the wipes automatically. This ensures hygiene and quality.

Our process uses automated machines for accuracy. It starts with choosing the right non-woven material. We select fabrics like organic cotton2 or bamboo based on the wipe's purpose. Next, we add a special liquid formula. This could be gentle for baby wipes or strong for cleaning wipes. Then, advanced machines cut and fold the wipes. Finally, these machines package the wipes securely. This keeps them moist and clean until you use them. Each step is controlled carefully to maintain high standards from start to finish.

Let's look closer at each stage.

- Material Preparation: We get large rolls of non-woven fabric. Machines unwind these rolls and sometimes treat them for specific properties.

- Solution Application: We mix the liquid formula in large, sanitized tanks. We carefully control the ingredients for consistency. Then, machines evenly soak the fabric with this solution as it passes through.

- Converting: High-speed machines cut the wide, wet fabric into individual wipes of the desired size. They also fold the wipes neatly using methods like Z-fold or C-fold, preparing them for packaging.

- Packaging: The folded wipes go into their final package. This might be a flexible soft pack with a resealable sticker or label, or a rigid plastic canister with a dispenser lid. Machines seal the packages tightly to prevent drying out and ensure tamper evidence.

How do we ensure quality control during production?

Making good wet wipes needs more than just production. Quality control is key at every step. So how do we make sure every wipe is perfect and meets strict standards?

We ensure quality through strict checks at multiple stages. We inspect raw materials before use. We monitor the process constantly for consistency. And we test the finished wipes thoroughly. This includes checks for moisture, strength, safety, and packaging integrity.

We take quality very seriously at BBWIPES. Our commitment is demonstrated through a comprehensive system designed to catch any potential issues early and ensure the final product meets your expectations and all regulatory requirements. Our detailed 4-Stage Inspection Protocol underpins this commitment.

Stage 1: Raw Material Screening

Quality starts with the ingredients. Before any material enters our production lines, it undergoes rigorous checks.

- Fabric Inspection: We verify the substrate matches specifications for weight, thickness, and composition. We also test its strength and absorbance.

- Liquid Component Testing: All liquid ingredients are tested for purity and concentration. Water used undergoes purification processes (like reverse osmosis) and testing.

- Microbial Screening: We conduct tests based on standards like ISO 11737-1 to ensure raw materials are free from unacceptable levels of microorganisms before they are used.

Stage 2: In-Process Monitoring

Constant vigilance during production maintains consistency.

- Solution Checks: We continuously monitor the liquid solution's pH level and ingredient concentration during mixing and application.

- Weight and Moisture Control: Automated systems check the amount of liquid applied to the fabric (product weight/saturation level) to ensure it's within the specified range (e.g., using 5-point checks per batch).

- Visual Inspections: Our trained personnel visually inspect the wipes during converting for defects in cutting or folding.

Stage 3: Physical Property Validation

The wipe needs to perform correctly in the hands of the end-user.

- Tensile Strength: We test the wipe's strength in machine and cross directions using methods like ASTM D5034 to ensure it doesn't tear easily during use.

- Dimensions and Fold: We verify that the cut dimensions and fold configuration match the product specifications.

Stage 4: Final Packaging Integrity & Finished Product Testing

The final checks ensure the product reaches the customer as intended.

- Seal Integrity: We use methods like vacuum chamber simulation and pressure testing to ensure package seals are airtight, preventing leaks or drying out. This confirms our 36-month shelf-life assurance.

- Final Microbial Testing: Representative samples from each batch are tested for microbial contamination to ensure product safety.

- Full Product Review: We check final weight, label accuracy, batch code legibility, and overall appearance.

Here's a simple overview of our testing focus:

| Stage | Key Focus Areas | Example Standard/Method |

|---|---|---|

| Raw Materials | Purity, Correct Specs, Microbial Load | ISO 11737-1 |

| In-Process | Solution Consistency (pH, Conc.), Saturation Level, Visual Check | Batch Monitoring |

| Physical Property | Wipe Strength, Dimensions, Fold Accuracy | ASTM D5034 |

| Final Packaging | Seal Strength, Leak Prevention, Final Microbial Check, Labeling | Vacuum Chamber Test |

This multi-layered approach allows us to maintain high quality consistently, batch after batch.

What materials are used in wet wipe production?

Not all wet wipes are the same. The materials we use change based on the wipe's job and your brand's positioning. What exactly goes into making them effective and suitable for their purpose?

We use two main parts: the wipe material (substrate) and the liquid solution. Substrates can be natural fibers like organic cotton or bamboo, or plant-based synthetics like PLA non-woven. The solution is typically purified water mixed with specific active ingredients.

Choosing the right materials is critical for performance, feel, cost, and environmental impact. We offer a wide range of options and guide you through the selection process.

Substrate Options: The Fabric Matters

The base material, or substrate, determines the wipe's texture, strength, absorbency, and biodegradability. We specialize in premium and eco-friendly options:

- 100% Organic Cotton: Exceptionally soft and gentle, highly absorbent, and naturally hypoallergenic. It's an excellent choice for premium baby wipes or sensitive skin facial wipes.

- Bamboo Viscose: Known for its silky softness combined with good strength. Bamboo is a rapidly renewable resource, making this a popular sustainable choice that is also biodegradable.

- PLA (Polylactic Acid) Non-woven: A plant-based plastic derived from renewable resources like corn starch. PLA wipes are compostable under industrial conditions, fitting well with strict environmental goals.

- Other Blends: We can also work with blends incorporating materials like Tencel™ (Lyocell) or standard materials like polyester/viscose blends depending on budget and performance requirements.

We help you select the perfect substrate density (measured in gsm - grams per square meter) and texture (e.g., plain, embossed, mesh) to match your product's application.

Solution Formulation: The Liquid Power

The liquid solution delivers the wipe's specific function. Our in-house R&D lab develops custom formulations tailored to diverse needs:

- Purified Water: The base for almost all formulations, treated to remove impurities.

- Cleansers & Surfactants: Gentle cleaning agents for tasks like baby cleansing or makeup removal.

- Moisturizers & Emollients: Ingredients like Aloe Vera, Vitamin E, Glycerin, or Argan Oil to soothe and hydrate the skin.

- Preservatives: Carefully selected, safe preservative systems are essential to prevent microbial growth after the pack is opened. We comply with regulations like the EU Cosmetics Regulation 1223/2009.

- Active Ingredients:

- Sanitizing/Disinfecting: Alcohol-free options (like using BZK or Citridiol® technology) or alcohol-based solutions for healthcare needs (meeting EN 14476).

- Soothing/Wellness: CBD infusions, essential oils (like lavender or chamomile), or specialized extracts.

- Pet Care Specific: Enzymatic cleaners for odor control, gentle formulations safe for animal skin (tested to ISO 10993).

- pH Balancers: Adjusting the formula to match skin's natural pH, especially important for baby and facial wipes.

- Fragrances: Hypoallergenic or natural fragrance options, or fragrance-free versions.

Our innovative AquaRise® technology allows us to achieve high efficacy (99.9%) with 30% less liquid. This reduces environmental impact and packaging weight.

How are custom formulations developed for wet wipes?

Sometimes a standard wipe isn't quite right. You might need a unique formula, a specific substrate, or a novel feature to meet market demands or stand out. How do we create custom wet wipes just for you?

We develop custom wipes through a collaborative process. We start by understanding your specific needs. Then, our R&D team selects materials and ingredients, creates sample formulas, and provides prototypes for your evaluation before full production.

Creating a unique wet wipe requires expertise and partnership. Our structured approach ensures the final product aligns perfectly with your brand vision and technical requirements.

Step 1: Discovery and Consultation

It all begins with listening. We discuss your project in detail:

- Target Audience: Who will use the wipe? (e.g., healthcare professionals like Emily Thompson needing validated claims, eco-conscious consumers like Henrik Sørensen demanding compostability).

- Intended Use: What is the primary function? (e.g., antiseptic cleaning, luxury skincare like Luca Moretti O M needs, wellness application for Priya Kapoor's startup).

- Key Requirements: Are there specific certifications needed (e.g., FDA, EU Ecolabel, Cradle-to-Cradle)? Any forbidden ingredients? Desired texture or scent profile? Budget constraints?

- Brand Identity: What are your brand values? (e.g., sustainability, clinical efficacy, premium feel).

Step 2: Material & Ingredient Strategy

Based on the consultation, our R&D experts propose suitable materials:

- Substrate Selection: Recommending options like organic cotton, bamboo, or PLA based on function, feel, and eco-goals.

- Liquid Formulation Concept: Identifying key active ingredients, potential preservative systems, and fragrance profiles. We leverage our expertise in areas like alcohol-free sanitizing (Citridiol®), hypoallergenic formulas, or CBD nanoemulsions for faster absorption.

Step 3: Laboratory Formulation & Prototyping

This is where the science happens:

- Benchtop Formulation: Our chemists create small lab batches of the proposed liquid formula.

- Prototype Creation: We produce a limited number of prototype wipe packs using the selected substrate and the trial formula. We typically include up to 3 prototype iterations free of charge.

- Client Evaluation: We send these prototypes to you for hands-on testing and feedback regarding feel, scent, performance, and packaging.

Step 4: Testing & Validation

Rigorous testing ensures the custom product is safe, effective, and stable:

- Compatibility Testing: We ensure the formula doesn't react negatively with the substrate or the packaging materials over time. This is crucial for shelf life.

- Stability Testing: We conduct accelerated and real-time stability tests to confirm the product maintains its physical and chemical properties and efficacy throughout its intended shelf life (we guarantee 36 months).

- Efficacy Testing: Depending on the wipe type, this may involve microbial kill-time studies (e.g., EN 14476), cleaning performance tests, or skin hydration measurements.

- Safety & Compliance Testing: This includes dermatological testing for skin products, regulatory compliance checks (e.g., FDA 21 CFR, EU Ecolabel), and potentially obtaining certifications like BPA-free or Leaping Bunny (Cruelty-Free). We assist with navigating these requirements.

Step 5: Scale-Up & Production

Once you approve the final prototype and all testing is successfully completed:

- Formula Finalization: Locking in the exact ingredient percentages.

- Process Validation: Ensuring our production lines can consistently replicate the custom product.

- Full Production Run: Manufacturing your custom wet wipes according to the agreed specifications and quality standards.

This systematic approach ensures that your unique vision for a wet wipe becomes a high-quality, market-ready reality.

Why Choose BBWIPES as Your Manufacturing Partner?

Choosing the right manufacturing partner is a big decision for your brand. You need reliability, quality, and expertise. Why should you consider BBWIPES for your wet wipe needs?

We offer reliability backed by 12+ years of specialized experience. We control the entire process with vertical integration. We excel at creating custom formulas, maintaining strict quality control, expertly navigating global regulations, and offering flexible order quantities.

We believe partnership goes beyond just making products. At BBWIPES, we are invested in your success. Here’s what sets us apart and makes us a trusted partner for brands worldwide:

Expertise Built Over Time

- Established Track Record: Since 2012, we've focused solely on premium wet wipe solutions.

- Global Reach: We export 85% of our products to demanding markets like the USA, Russia, France, and the UK, meeting diverse international standards.

- Proven Success: We have tangible success stories, like developing bespoke wipes for a French luxury hotel chain, co-engineering FDA 510(k) cleared wipes for a US hospital network, and supplying multilingual wipes for Dubai Airport Authority.

Control and Customization Power

- True Vertical Integration: Owning raw material processing and R&D labs gives us unparalleled control over quality, speed, and innovation, avoiding third-party delays.

- Custom Formulation Expertise: From material selection (organic cotton, bamboo, PLA) to advanced solutions (alcohol-free sanitizing, CBD infusion, hypoallergenic care), we create wipes tailored precisely to your needs.

Unwavering Commitment to Quality

- Certified Facilities: Our Wenzhou headquarters operates under ISO 9001, GMP, and ISO 22716 certifications.

- Rigorous 4-Stage Inspection: We implement meticulous quality checks from raw materials (ISO 11737-1 screening) through in-process monitoring (pH/absorbency checks) to final product validation (ASTM D5034 strength tests, vacuum seal testing).

- Compliance Assurance: Our products meet standards like FDA 21 CFR, EU Ecolabel, REACH, and are dermatologically tested. We hold certifications including Cruelty-Free International Leaping Bunny and source FSC-certified packaging.

Sustainability as a Core Value

- Eco-Conscious Innovation: We pioneered AquaRise® technology (using 30% less liquid) and champion biodegradable/compostable materials.

- Ethical Operations: We are Sedex SMETA ethical audit compliant, ensuring responsible practices.

Agile and Client-Focused Operations

- Efficient Logistics: We offer temperature-controlled shipping, fast lead times (12-day standard, 7-day express available), and flexible shipping terms (DDP/DAP).

- Flexible MOQs: We accommodate different scales, starting at 10,000 units for stock designs and 50,000 units for custom formulations.

- Dedicated Support: Benefit from 24/7 lab support, free compatibility testing (up to 3 iterations), $2M product liability insurance, and carbon footprint reporting with your orders.

Partnering with BBWIPES means gaining a dedicated team committed to delivering high-quality, compliant, and innovative wet wipe solutions that elevate your brand.

Conclusion

Making wet wipes involves careful steps from choosing suitable materials and liquids to precise converting and secure packaging. Consistent quality control throughout this process is absolutely essential. Choosing an experienced, vertically integrated partner like BBWIPES ensures you receive high-quality, compliant wipes specifically tailored to your brand's unique needs. Let's discuss your project today.

-

Understanding non-woven fabric is crucial for selecting the right materials for effective wet wipes. Explore this link to learn more about its properties and applications. ↩

-

Organic cotton is a popular choice for sensitive skin products. Learn about its advantages and why it might be the best option for your brand. ↩